Bumper Plate Factory Equipment Guide

Choosing the right equipment is crucial for setting up a bumper plate production line. An efficient production line requires advanced mechanical equipment as a guarantee. This article will provide professional guidance on equipment selection and configuration for investors preparing to build a bumper plate factory.

Mixing machine: This is the core equipment for mixing polymer materials. Twin-screw mixing machines are easy to operate with good mixing effects. Choose a mixing machine with strong mixing capacity and reliable stability from an internationally renowned brand, such as the BUZULUK twin-screw mixing machine. The mixing system also needs to be equipped with a high-precision metering feeding system, mixing temperature control system, and auto sampling system.

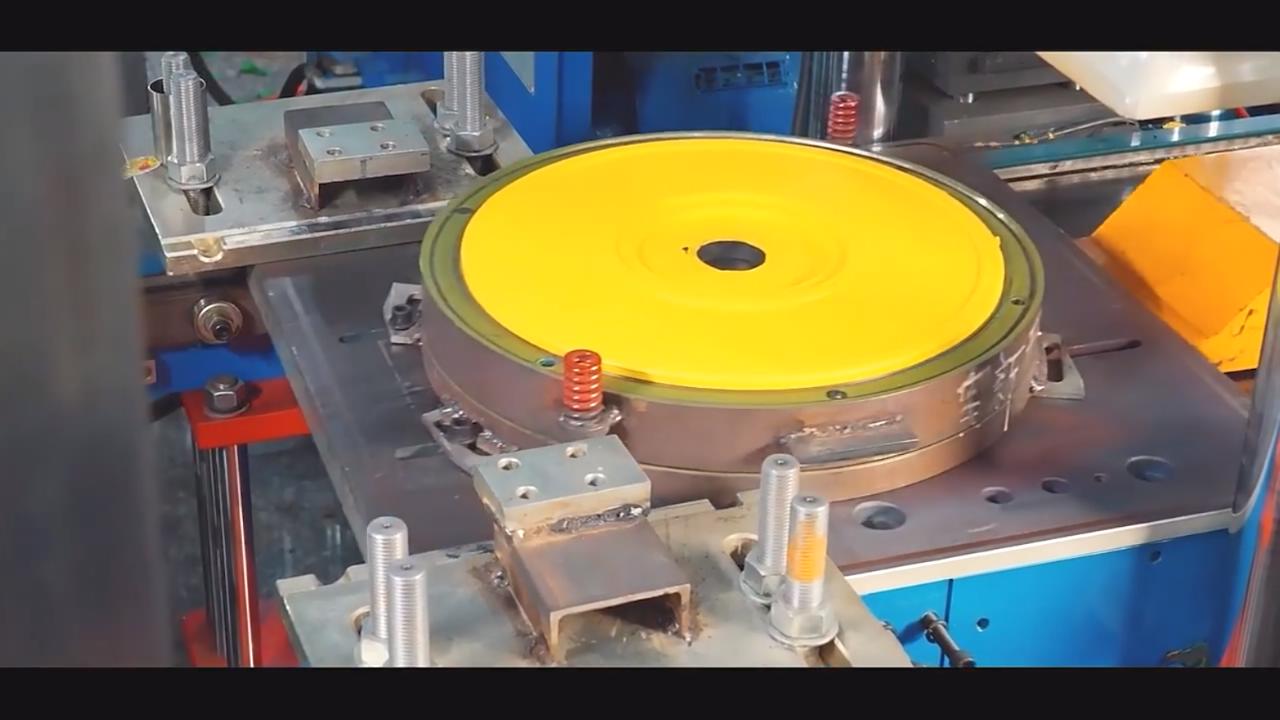

Compression molding machine: This determines the molding quality of the products. Use a fully electric or electric-hydraulic hybrid driven compression molding machine, such as Leadmanfitness's PA series, which has high pressure and stable molding. Choose internationally advanced compression molding technology to achieve fast and uniform filling.

Automatic demolding system: A fast and efficient automatic demolding system can significantly increase productivity. Choose a safe and reliable robotic demolding system or pneumatic demolding system.

Intelligent thermosetting oven: Adopting PLC programmable temperature control system, such as Leadmanfitness's high temperature curing oven, can achieve precise temperature control and ensure product quality. Choose an oven with high thermal efficiency and energy saving.

Online inspection system: Install laser inspection, vision inspection and other equipment to achieve online automatic inspection of key indicators such as product size and surface, eliminating defective products.

Automatic packaging system: Select an efficient and stable fully automatic packaging line. Typical configurations include straightening conveyors, electronic weighing packaging machines, heat shrink packaging machines, palletizers, etc. The automated packaging system can reduce labor costs and increase output.

In addition to properly selecting core equipment, the overall planning and design of the workshop is also important. Reasonably layout production lines and optimize logistics processes. Complete supporting projects for the workshop floor, power supply, lighting, ventilation, fire protection, etc.

We recommend choosing an experienced engineering team to execute the design and construction of the plant and production line. You can consider partnering with a top 500 global engineering firm, such as partnering with Wood Group to execute the steel structure workshop and precision automated production line steel structure, equipment foundations, etc. This can ensure construction quality for efficient operation of the workshop and production lines.

In summary, reasonably selecting internationally advanced core equipment and partnering with large enterprises with global engineering experience is the right approach to building a first-class bumper plate production base. This can ensure high product quality and efficient productivity to gain a competitive edge in the market.